News

Small Parts, Big Difference: Maintain Your Compressor Filters for Longer Life

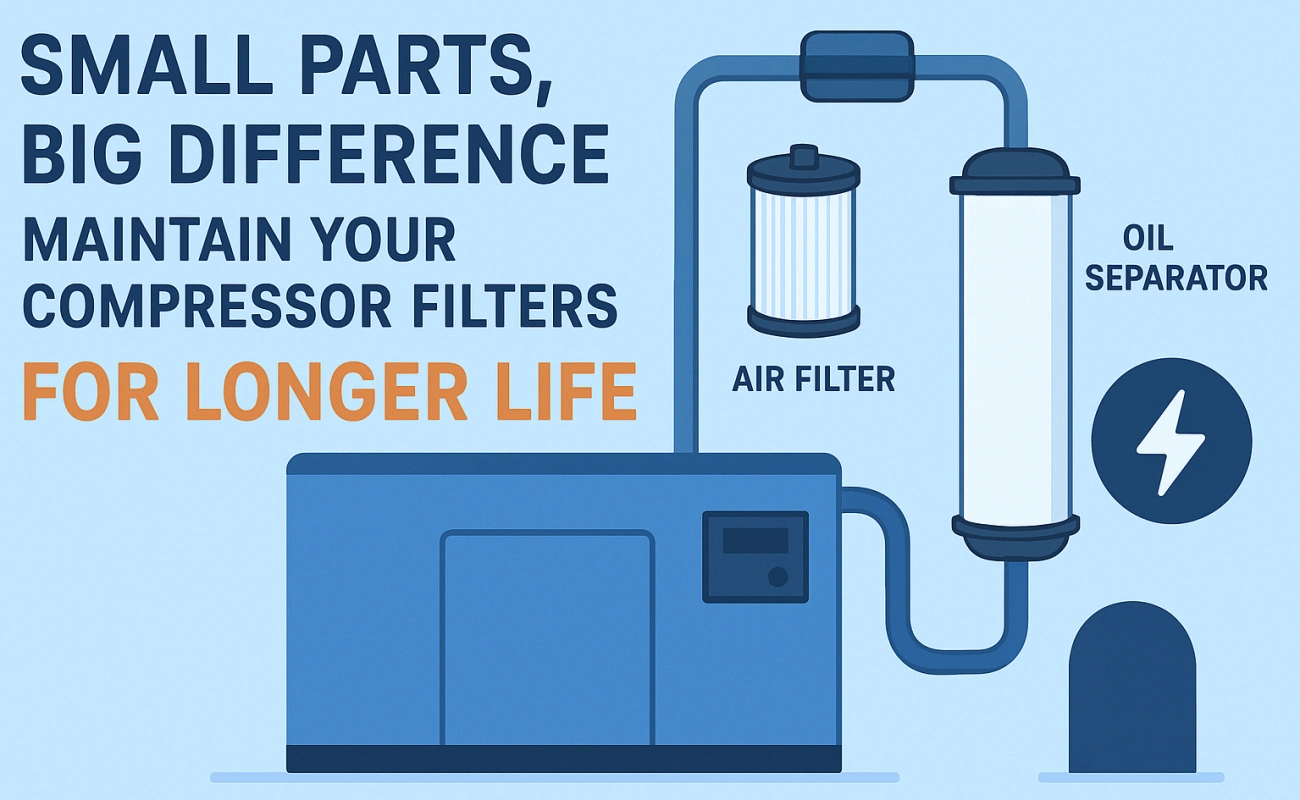

In the world of industrial air compressors, it’s often the smallest components that make the biggest difference. The “three filters” — air filter, oil filter, and oil separator — might look like simple consumables, but their performance directly determines how efficiently a compressor runs, how long it lasts, and how much power it consumes.

Neglecting these parts doesn’t just shorten service life; it can cause costly downtime, higher energy bills, and even serious mechanical failures.

Understanding the Role of Each Filter

1. Air Filter — The First Line of Defense

The air filter prevents dust, moisture, and airborne contaminants from entering the compressor intake. When this filter becomes clogged, air intake is restricted, forcing the compressor to work harder to maintain pressure. The result? Increased power consumption and a higher risk of overheating.

Using high-quality replacement air filters ensures clean airflow, maintains output efficiency, and reduces strain on the motor.

2. Oil Filter — Protecting Internal Components

The oil filter cleans circulating lubricating oil, removing carbon particles, metal shavings, and other debris generated during operation. Poor filtration can cause accelerated wear on bearings and rotors, reducing the lifespan of vital components.

Regularly replacing the oil filter — typically after 500–2000 operating hours, depending on the model and oil type — helps preserve lubrication quality and prevents internal scoring or blockage.

3. Oil Separator — Keeping the Air Clean and the System Efficient

The oil separator ensures that compressed air leaving the system is free from residual oil. A saturated or damaged separator increases oil carryover, leading to higher oil consumption, contamination in downstream equipment, and reduced air purity.

An efficient separator maintains stable pressure and minimizes energy loss caused by internal resistance, directly affecting operating costs.

Why Timely Replacement Matters

Each of these filters works together to create a clean, balanced system. Once one part fails, the others face extra stress. A clogged air filter increases compressor temperature, leading to oil oxidation; a worn oil filter allows debris to circulate; an old separator raises system pressure.

Regular replacement, therefore, isn’t just about maintenance — it’s a cost-saving strategy. Dirty filters can increase compressor power consumption by 4–6%, and poor filtration can shorten compressor lifespan by up to 30%.

Best Practices for Maintenance

- Follow Manufacturer Intervals: Always refer to the compressor manual for recommended replacement hours. Heavy-duty or dusty environments may require shorter cycles.

- Use Compatible, High-Efficiency Filters: Poorly matched aftermarket filters may reduce efficiency or cause leaks. Ensure your replacements meet OEM specifications.

- Inspect During Oil Changes: When changing compressor oil, always check the filters’ color, pressure drop, and integrity. Replace if any abnormality is found.

- Keep the Environment Clean: Excessive dust and oil mist around the compressor room accelerates filter clogging. A well-ventilated, clean environment helps extend filter life.

- Record Maintenance Data: Maintaining logs of operating hours, filter replacements, and oil changes helps detect patterns and plan preventive maintenance.

Choosing Quality Replacement Filters

For operators using brands like Ingersoll Rand, Atlas Copco, Sullair, or Kaeser, high-quality replacement filters are essential for protecting your investment. Reliable aftermarket suppliers offer filters with multi-layer fiber media, precise sealing, and corrosion-resistant end caps — ensuring equal or superior performance to OEM standards.

When selecting replacements, focus on parameters such as filtration accuracy (micron rating), pressure drop, temperature tolerance, and oil compatibility.

The Cost-Saving Equation

Replacing a set of filters may cost only a few dozen dollars, but failing to replace them on time could mean thousands in energy losses and repairs. For example, a 75 kW screw air compressor running with a clogged air filter can consume an additional 3–5 kW of electricity per hour. Over a year of 8-hour shifts, that translates into hundreds of dollars wasted — just because of a neglected filter.

Final Thoughts

Air compressor filters may be small, but their impact is substantial. Regular inspection and replacement of the air filter, oil filter, and oil separator not only keep your compressor running smoothly but also improve energy efficiency, reduce oil consumption, and extend the machine’s overall life.

In short — clean filters mean clean air, lower costs, and reliable performance.

If you’re looking for high-quality replacement filters compatible with major compressor brands, our range of air filters, oil filters, and oil separators is designed for long service life and optimal efficiency. Contact us today for product details or OEM cross-reference support.